Hello, my dear friends, today I would like to introduce several auxiliary products developed and produced by Weitong Technology: palletizer (including shaping), flip palletizer, and depalletizer. Although these three devices are inconspicuous, they play a vital role in intelligent warehousing and intelligent loading and unloading processes. They not only improve the efficiency and accuracy of cargo loading and unloading, but also reduce labor intensity and safety risks, becoming an important tool for enterprises to reduce costs, increase efficiency and increase production capacity.

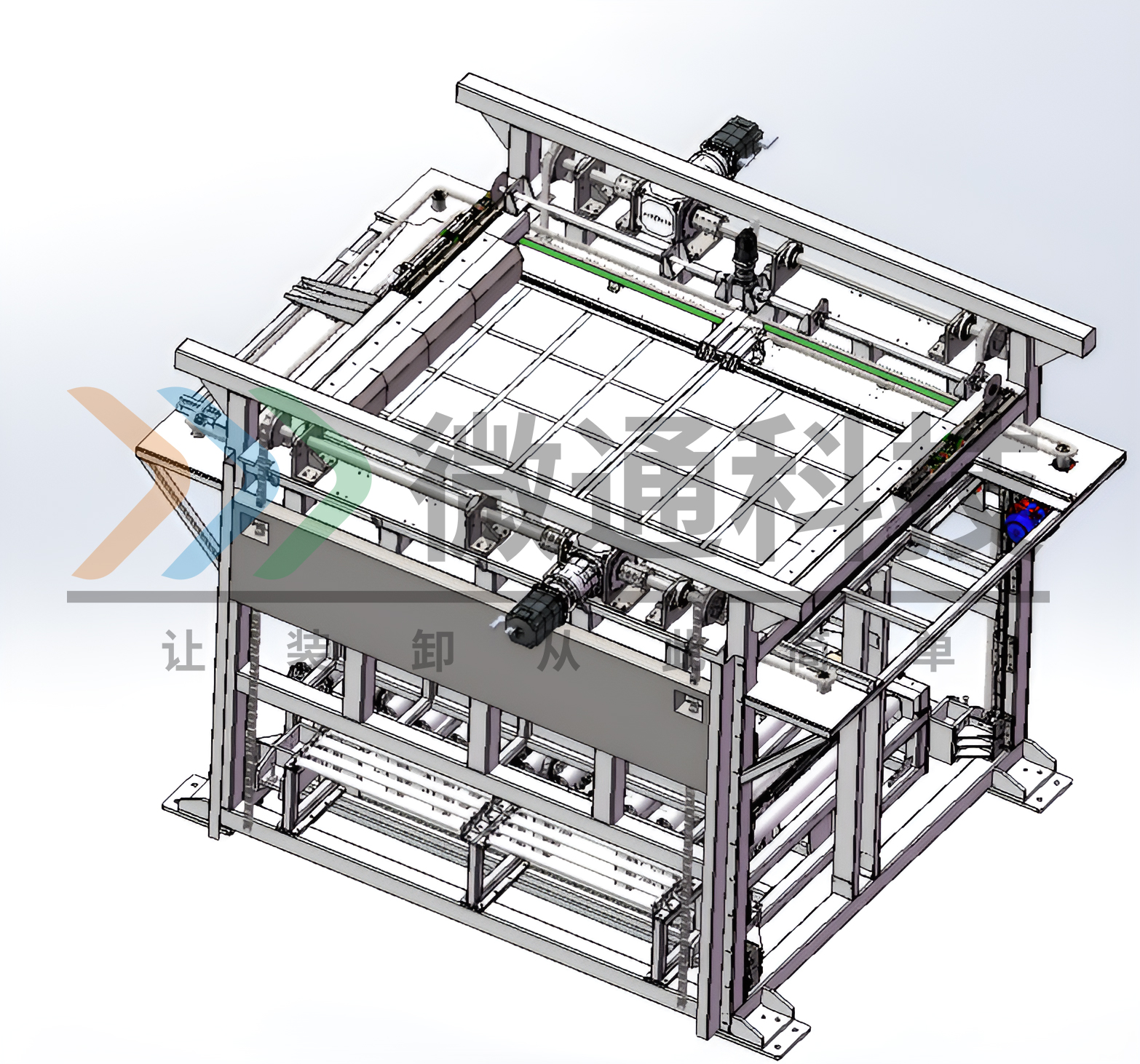

Palletizer (including shaping):

Palletizer mainly stacks the bagged materials delivered by the conveyor on the pallet according to certain rules to form a neat and standardized stacking shape, and transports the stacked materials

Palletizers are usually equipped with shaping devices, which can fine-tune the items during the palletizing process to ensure that each stacking shape meets the preset standards. This shaping function is crucial to improving the cleanliness of the warehouse and the safety of the items.

The equipment can be seamlessly connected with AS/RS, automatic guided vehicles (AGV), automatic conveyor lines and other equipment to achieve an automated and continuous operation process.

Product parameters:

Loading efficiency: 1600-1800 bags/hour

Suitable for bagged materials

With stubble pressing and shaping functions

Maximum width can reach 2.4 meters

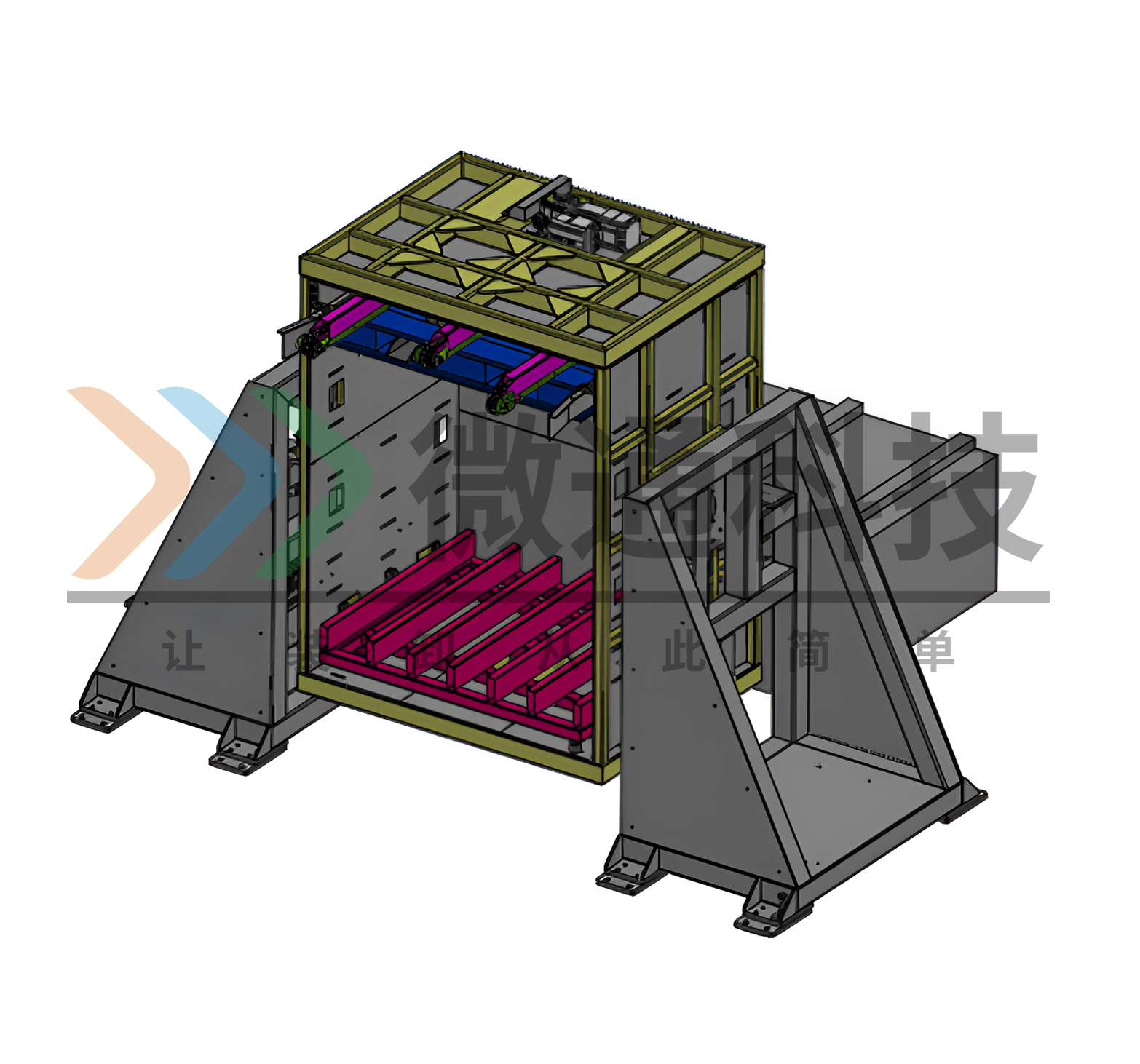

Turning and unloading palletizer:

Turning and unloading palletizer is mainly used to flip the items on the pallet to a certain angle to facilitate the removal of the pallet for subsequent packaging and automatic loading, which can greatly improve the loading and unloading efficiency and safety of the items. Through automated flipping and unloading operations, manual intervention can be reduced, labor intensity can be reduced, and items can be prevented from being damaged during the flipping process.

The equipment can be used in conjunction with AS/RS, automatic guided vehicles (AGV), automatic conveyor lines and other equipment to realize the automation and intelligence of the entire process.

Product parameters:

Loading efficiency: 60 pallets/hour

Automatic return of pallets to the warehouse

Interfacing with stereoscopic warehouses, conveyor lines, AGVs

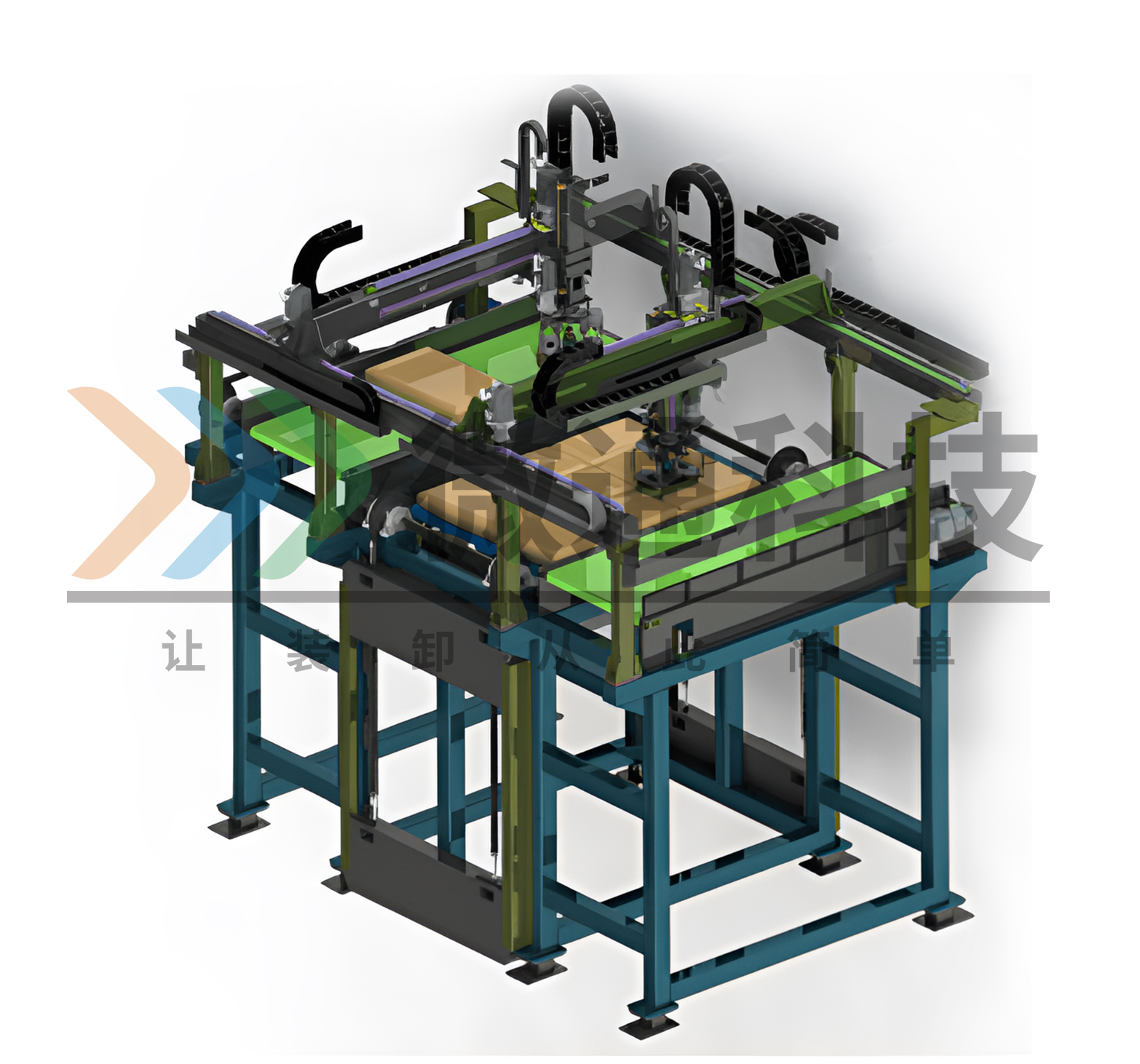

Depalletizer:

Depalletizer is mainly used to take out the items on the pallet one by one for subsequent processing, sorting or storage operations. This equipment has a wide range of applications in automated warehouses, production lines and other fields.

Depalletizers can greatly improve the efficiency and accuracy of depalletizing items. Through precise identification and positioning technology, depalletizers can accurately take items from pallets and place them in designated locations.

The equipment can be seamlessly connected with automatic conveyor lines, sorting machines and other equipment to form a complete automated operation process.

Product parameters:

Loading efficiency: 1000 bags/hour

Maximum single bag load 50kg

Adapt to woven bags, kraft paper bags,

Paper-plastic composite bags, surface coated bags, etc.

In summary, palletizers (including shaping), flipping depalletizers and depalletizers play a vital role in smart logistics and automatic loading and unloading processes. They not only improve logistics efficiency and reduce labor costs, but also ensure the safety and integrity of goods during handling and storage. With the continuous advancement of technology and the widespread application of intelligent systems, these devices will play a more important role in the future, promoting the continuous upgrading and development of smart logistics and automated loading and unloading processes.